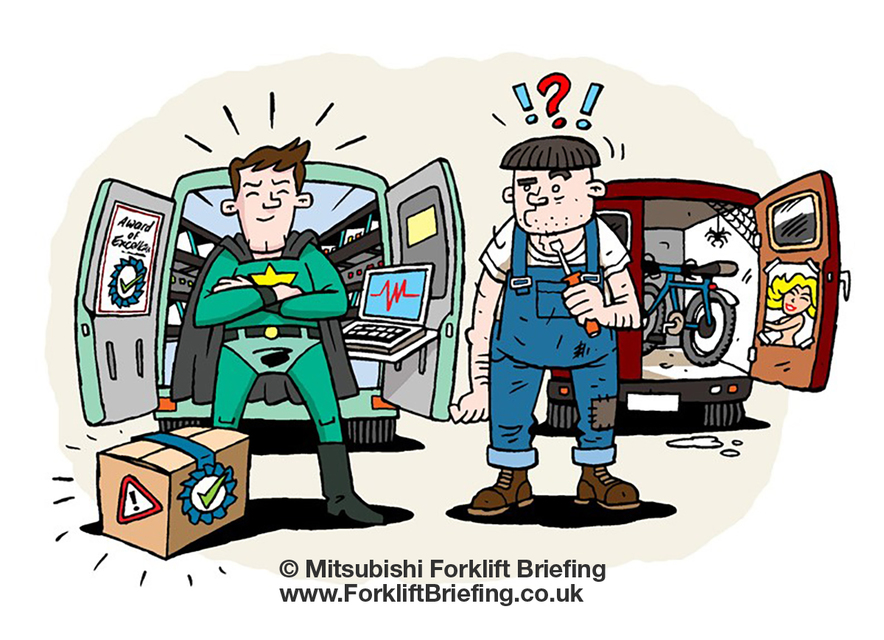

Hero or zero?

What sets a part apart?

When in the market for a forklift, how much do you consider beyond the truck itself?

Purchasing or renting a lift truck is quite an investment, so protecting that investment should be high on your list of priorities. Because it’s not just about acquiring a vehicle and that being the end of it, it’s about the support and service during the machine’s lifecycle… and it’s certainly about the parts used.

Efficient parts supply is essential to keeping lift trucks in action and maximising productivity. Uptime is such a key element of materials handling, but with so much competition in the market there is often far too much focus on price over quality and availability.

But what makes a parts supply setup good?

If you’re in the process of looking for a new truck, it should become routine practice to speak to your dealer not only about the quality of the truck, but also the quality of their maintenance. After all, you want to be confident that the work being carried out and the materials used will be of the highest standard. Find out how they train their engineers. Ask them how and where they source the parts that they’ll be using on your truck when the time comes.

One of the really key factors is ensuring that parts they use are always available as soon as possible when needed, and not just at the dealership, but straight from their service vans as well.

A good example would be Mitsubishi Forklift Trucks’ parts facility. The team there works to support dealers across Europe, the Middle East, CIS and Africa — a complex task at the best of times. Through advanced warehouse management and logistics coupled with high levels of dealer support, they manage to deliver 97% parts availability, and this becomes even more remarkable when you understand the criteria are ‘full line, first pick’.

In simple terms, this means that even if an order contains 37 parts in various quantities, and just a single item from that entire order is missing in stock, this would be marked by the manufacturer as a failure.

Even if that one item is certain to arrive the next day.

These are the standards you should demand when making your purchasing and hire choices.

Hero or zero?

And with so many parts available on the market, don’t underestimate the importance of the engineer using genuine parts. After all, the truck has been developed with only approved parts and is designed to work and wear as a complete system. They were picked for their longevity and quality, so using other parts during the truck’s lifetime could negatively affect the truck’s performance or lead to unexpected failures.

The temptation for dealers to use cheaper parts is understandable, but the chance is there that they may break sooner or fit just that little bit less well. Look for dealers who deliver only the best service, because if anything goes wrong then it could hurt your business, so you want them to take no risks.

When uptime is so vital, why would you put your trust anywhere else?

Conclusion

While parts may sometimes even be of similar quality at slightly different prices, never underestimate the benefit of a parts supply that you know will be immediately available and with you right away.

- Action points

- Contact your dealer to discuss their options about preventive maintenance.

- Find out more about their whole approach to servicing and maintenance, from training to parts. Discover what you can expect from them throughout the lifetime of the truck.