social distancing

Preparing your warehouse for the 'new normal'

The COVID-19 crisis has had a huge impact on us for many months now. Despite the easing of measures in many countries, it remains unclear when we can leave this all behind us. The most optimistic spirits see us starting up before the summer; the pessimists foresee a dark 2020 for all logistics operations. In the meantime, we have all had to deal with the ‘new normal’ and work remotely if possible.

But what can we learn from this pandemic? Uncertainties are ever present and resilient companies try to react in a way that enables them to come out stronger once the markets revive. Let’s explore a few opportunities:

1. Ensuring social distancing

Regardless of how quickly things get back to normal, it seems that social distancing will be a keyword for a long time to come. Most businesses have already ensured the required distance with simple interventions such as adhesive tape and temporary barriers. However, this may also be a good time to invest in modern, technological solutions that will prove useful even after the crisis.

Consider the innovative technology which uses artificial intelligence and cameras to warn when forklift drivers get too close to each other. Simpler tech solutions can also be very useful, such as the Safety Zone system from Mitsubishi, which warns when pedestrians get too close to the counterweight.

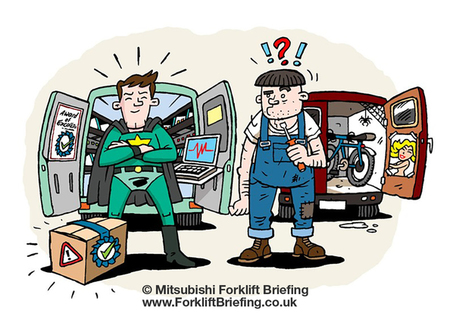

2. Combine a regular site inspection with a safety risk assessment

We have written before about how site inspections can prevent accidents and improve productivity. Whilst it makes sense in any case to do this annually, yours may be one of those businesses currently experiencing a fall in demand and activity due to the crisis. If so, this could be an especially good moment to conduct such a site inspection and to combine it with a thorough safety risk assessment.

Chances are, you are already adapting your workplace to adhere to the ‘safety distances’ recommended in your country, but why not seize the opportunity to improve safety even further? Check out your loading docks (to prevent falling!), re-evaluate how you separate materials handling equipment from pedestrians, and make a traffic plan for intersections. Make an extensive list, followed up by an action plan.

3. Reduce your inventory and free up financial resources

In times of prosperity, it may not always be a problem if inventories are too high. But when cash flows are in danger, it pays to optimise stock levels. Basically, it boils down to balancing the need to fulfil orders against reducing the amounts of cash tied up in inventory. Experts can help to reduce obsolete stock, by setting up an analysis and KPI system for inventory categories, while stock levels can be minimised and ordering amounts optimised.

Today, as the pandemic’s effects put timing and reliability of deliveries under great pressure, this exercise will help you lower operational costs, eliminate delivery emergencies and improve warehouse processes. At the same time, it will help you to cope better with adverse events in the future.

- Actions:

- Research the possibilities for investing in technology to ensure social distancing

- Plan a combined site inspection / safety assessment activity and make a follow-up plan

- Invite an expert to discuss how to optimise your inventory management