Truck vibrations: Is your business falling foul of the law?

Lowering your forklift's travelling speed can greatly reduce the level of body vibrations created.

Body vibrations on forklift trucks have been a hot topic from the moment European Directive 2002/44/EC shone the spotlight on them. The big question is whether the use of damping techniques and better seats is really worthwhile? Wouldn't it be  better to meet the directive another way?

better to meet the directive another way?

A recent series of on-site tests provide the answer.

According to Directive 2002/44/EC on body vibrations, employers must prevent their employees from being exposed to vibrations greater than 1.15m/s2. The same directive also states that employers must take preventative measures if vibrations over an eight-hour workday exceed the action value of 0.5m/s2. In an attempt to meet these conditions, forklift manufacturers are using different techniques including suspension (floating) cabs, suspended powertrains (in diesel trucks), and minimum clearance for mast and chassis. More attention is also being paid to the quality of the driver's seat and the type of tyres fitted.

Seats, tyres, surfaces

Extensive testing revealed that these measures do have a positive effect on reducing body vibrations. A good seat, for example, helps cut vibration levels - but only if it is correctly adjusted to suit the body weight of the driver. Beware, though... a wrongly adjusted seat actually amplifies vibrations!

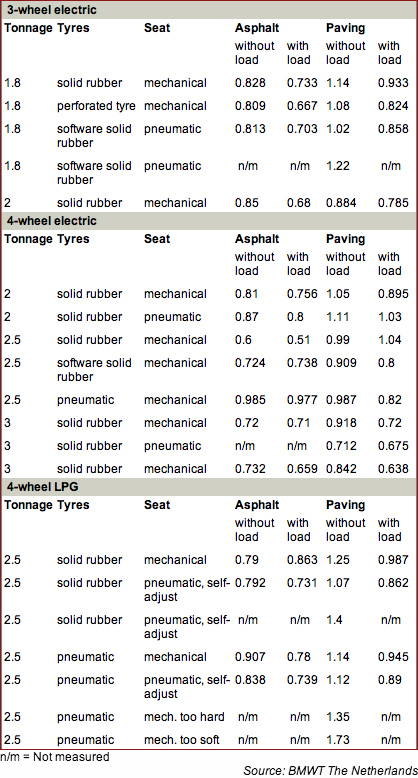

In the tests, a variety of forklift trucks - both electric and IC engine - were then run with a range of different tyres. Testers measured vibrations on trucks fitted with solid rubber and pneumatic tyres, as well as with solid rubber tyres which had perforations in the intermediate layer. They ran the trucks over three different surfaces: relatively flat asphalt, paving stones and rain gutters. Across all three surfaces solid rubber tyres produced the best results - and those with perforations performed best of all. On asphalt, the pneumatic tyres were found to create an imbalance that actually increases vibrations. Indeed, these tyres only performed well on paving stones while carrying a load.

Speed decides all

Naturally, most of the tests involved modern trucks, seats and tyres. Just for comparison's sake, measurements were also taken on a 20-year-old electric forklift truck with a rattling pallet box tipper, worn cushion tyres and a seat without suspension. Astonishingly, this truck had the lowest vibration values of all! Why? Well, this truck had a much lower travel speed than its modern competitors and that is the key to really cutting vibrations. But before you drag your old truck from the knacker's yard, remember that cutting driving speeds will have exactly the same effect on a modern truck.

Our conclusion?

Virtually no forklift trucks on test could perform below the legal limit of 0.5m/s2 in an eight-hour day. To get your vibrations as low as possible you need to ensure the ground is as smooth as possible; suspension seats must be correctly adjusted to body weight and the right tyre is a must. Finally, cutting speed - especially when crossing awkward terrain - will deliver the greatest reductions of all.

- Action points

- Post reminder to drivers to check seat adjustments

- Book vibration testing

- Reduce speed limits