Forklift tyres: the crucial test that too many companies fail

Forklift tyres: the crucial test that too many companies fail

Your forklift's tyres do a lot more than help your truck move around the warehouse... Unlike car tyres, those on a forklift are absolutely necessary to keep your operation stable and safe. But how do you know when a tyre becomes dangerous? And how can you stay safe for longer?

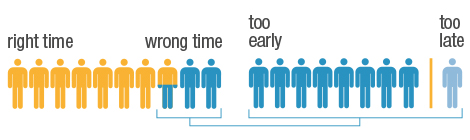

Frighteningly, it's an area where 28% of companies get it wrong: 3% of tyres are replaced too late (which puts operators and their co-workers at risk) - while 25% of tyres are replaced too soon (wasting natural resources and cash).

Above: one in four forklifts have their tyres changed too early.

The best approach is to get the maximum wear from every Euro you spend on tyres - and then change them at exactly the right moment to be safe. Here are five tips to help.

Tip #1: Choose the right tyre for the job

There are three types of tyres. Pneumatic tyres suit high speeds over distances, but can be vulnerable to punctures; press-on solid tyres are for smooth surfaces only and resilient tyres are a hybrid of the two. For many companies, this last category meets their needs. Resilient tyres comprise three layers of material: top (an anti-abrasive layer), middle (a soft, shock-absorbent layer) and base (a rigid base to ensure tyres are fitted securely).

If you're in any doubt at all, ask your Mitsubishi forklift dealer for advice on the best tyres for your truck and workplace.

Tip #2: Quality affects performance, wear and safety

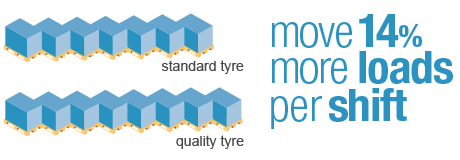

Good quality tyres can move 14% more pallets in a single shift (as reported in our article Cheap tyres - are they worth the risk?). Manufacturer-approved tyres may look more expensive at first, but their long-term impact on safety, productivity and maintenance costs can mean they're really the most economical option.

Quality tyres make a big difference not only to safety but also to productivity. A good investment for forklift operators where higher throughput means higher profit.

Also, tyres with cheaper compounds wear more quickly - and less evenly. As a result, trucks can be running dangerously below the 'standard' 60J line - in places.

Remember: quality is about more than just the tyre itself. To get the best results, look for ISO9001 process controls from your tyre manufacturer and fitter.

Tip #3: Tyre safety impacts truck stability

When a tyre fails, the tyre itself is the least of your worries. Tyres are most likely to come off the wheel when under high stress, such as cornering with a heavy load - so you're looking at dropped loads, and even the risk of an overturn. Read more...

Sudden tyre problems can result from bead wire failure, slippage on the rim, tread separation and poor fitting, such as radial cracking from over-locking a tyre.

Sudden tyre problems can result from bead wire failure, slippage on the rim, tread separation and poor fitting, such as radial cracking from over-locking a tyre.

Tip #4: Accidents happen when the heat is on

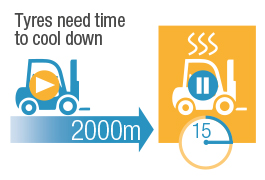

Heat is the number-one danger to tyre rubber - and they need time to cool down. As a rule of thumb, tyres can go 2 km before they need a 15-minute break.

Above: It is surprising how quickly 2000 metres is covered in a normal shift. Tyres that are not 'rested' after that distance can quickly overheat and reduce their service life - or worse, fail.

But as the amount of natural rubber in a tyre decreases - whether due to wear, or cheap tyre compound and construction - there is less opportunity for heat to spread out... so the risk increases significantly.

Tip #5: Think about your steering

Maximising tyre safety isn't just about choosing the right tyre: it's about the right truck, too. Some forklift trucks are carefully designed to preserve tyres when they steer - for example, the rear wheels on the new Mitsubishi EDiA turn out to a full 100 degrees, while four-wheel drive also minimises tyre load.

Many forklifts' steer wheels 'push' on tight turns - meaning the rear tyres slide on the floor. Well-designed steering systems (like the Mitsubishi EDiA EX, shown above) do not 'push', extending tyre life and improving safety.

The result? Tyres stay fresher, safer and more productive for longer - saving you money, while also delivering more productivity every day.

Hint: look out for black rubber marks on your warehouse floor. They're a sign of excessive tyre wear.

Conclusion: check your tyres before every shift

As obvious as it sounds, simply checking your tyres' condition, damage and wear can improve safety, cut costs, and make your trucks more productive. If the tyres are fine, you can use them longer and save money - and when the tyres become unsafe, you can prevent damaging goods and the risk of a serious injury to your team. Either way, you win.

If you'd like any guidance on tyre choice and inspection procedures, your Mitsubishi Forklift Trucks dealer will be happy to help.

- Action points

- Check for tyres adhering to ISO9001 standards

- Give tyres a regular “cooling off” period

- Look out for rubber marks on warehouse floor

- Contact your local Mitsubishi forklift trucks dealer