Mousetrap deaths now top workplace killer

How one simple step can avoid tragedy in your firm

Recent studies by the European Agency for Safety and Health at Work (OSHA) make grim reading for forklift operators. Tipping accidents are confirmed as one of the biggest causes of fatal accidents in the workplace. In almost all of these cases, the driver was ‘mousetrapped’ between the truck and the ground, causing massive trauma to the head or upper body.

But it need not be like this.

In this issue of Forklift Briefing we explain why trucks tip over - because experts believe that this is not fully understood by many forklift drivers.

And while that should be useful, we start this month’s article with a simple truth that you can put into action today to help save the lives of your colleagues and avoid business-busting fines and compensation claims.

Belt up or get cut up

In car driving, the seatbelt system was introduced to restrain the driver in a high speed collision – preventing him or her from hitting the steering wheel or windscreen. So why do forklift trucks have a seatbelt… surely their speeds are much lower?

The surprising truth is that the seatbelt on a forklift is not intended to protect the driver from a collision at speed, but to stop him from his natural urge to jump free.... to his death.

Seatbelts in forklifts are designed to prevent drivers sliding from the seat in an upward and outward direction, as doing so increases the risk of a driver having his head trapped or crushed between the overhead guard and the floor.

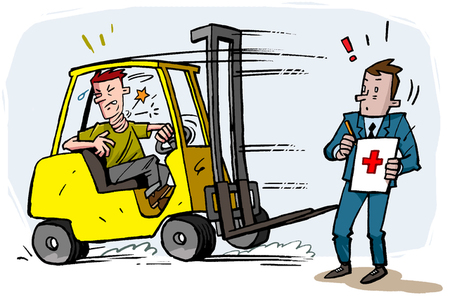

Coroners’ Inquests hear ever more tragic and gruesome cases of how, as a forklift truck starts to tip over, the human brain makes the driver try and get out of the truck. And how, in trying to save themselves in this way, they often die. The driver is ‘mousetrapped’ between the overhead guard and the ground with fearful injuries.

|

No amount of training, experience or knowledge seems to stop people trying to ‘beat the mousetrap’.

If only the driver could keep his nerve, stay inside the cab, perhaps bracing himself with the steering wheel or grab handles. The driver may be bruised, but there are virtually no fatalities on record of this type of accident.

Studies have shown that the urge to jump is so irresistible that the best safety precaution of all is to wear a seatbelt – to stop the driver jumping out!

So this is what you can do today to start saving lives: make it a company rule that every driver must wear their seat restraint at all times. If you see someone in your workplace driving without a seat restraint, stop them and insist they wear it. Make sure your colleagues know the story too.

It may not be very ‘macho’ to belt up on a slow-moving forklift, but remember it is better to belt up than to get smashed up…

Above: when a truck starts to tip it is imperative that the driver stays inside the cab.

Why forklifts fall

There are many situations that can lead up to a tipping incident, but in all cases the truck’s stability has been compromised by poor driving and poor understanding of the basic principles of forklift stability.

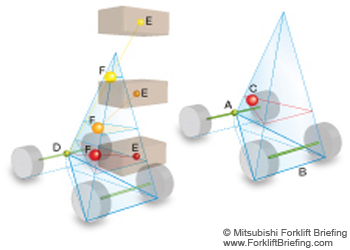

At the heart of truck stability is the so-called Stability Pyramid. Forklift trainers recognise the pyramid as one of the most difficult yet important concepts to teach. A major problem – recognised by health and safety regulators – is that there is not enough training time to ensure this principle is actually understood.

|

How does the centre of gravity move?

The point that must be kept within the triangle/pyramid is the combined centre of gravity (CCOG). The truck itself has its own centre of gravity, typically about 20cm below the driver’s seat. In addition, the load has a centre of gravity – the load centre – typically 500mm forward of the fork backrest. These two forces form the combined centre of gravity: a new, moving, centre of gravity that must stay inside the Stability Pyramid. If this point moves beyond the front of the pyramid, the truck will tip forward. If it leaves the pyramid to left or right, the truck will tip sideways.

When stationary, the CCOG can always be found on a line drawn from the truck’s centre of gravity to the load centre – as the load is lifted, the CCOG moves upwards with it – into a smaller and smaller triangle…

Why is it a triangle?

Many forklift drivers struggle with the idea of the base of their stability pyramid being a triangle and not a square with a wheel on each corner – especially on a four wheel forklift. In fact, the pyramid’s base joins the front two wheels on the ground with the pivot point on the rear steer axle – so even on a four wheel truck, it is a triangle, with one point over the rear axle pivot.

Most people think of a ‘pyramid’ as having a square base, like those in Egypt. A triangle-based pyramid is actually called a tetrahedron. Keeping the CCOG inside a triangle is even harder than a square, because it is smaller!

More height, more danger

Because the pyramid rapidly narrows to a point, loads that are very stable at low lift height quickly become unstable at higher lift – as the CCOG must be kept in a smaller and smaller triangle. At high lifts, this triangle can be surprisingly small – with very little margin of error.

More speed, more danger

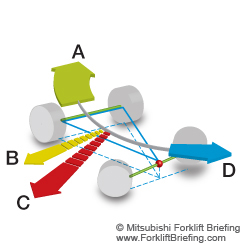

Unfortunately the centre of gravity is not the only force at work. In a moving truck there are additional forces – caused by the truck’s acceleration and deceleration. Even quite gentle braking can move the effective CCOG forward – out of the triangle – creating the risk of tipping.

|

Worse still are the dynamic forces caused by turning – which push the truck sideways in the opposite direction of the truck’s turning direction. See figure 3.

These forces may be small at low speeds, but they do move the CCOG and with an elevated load there is a very small triangle to keep the CCOG within. This is why properly trained drivers will never manoeuvre or travel with an elevated load.

No load, no danger?

Driving without a load is not a guarantee against a truck overturning. Unloading a vehicle moves the CCOG to the rear, increasing the risk of tip over. And this is frequently seen when joyriding in an unloaded truck. Forklifts are designed for manoeuvrability and pulling power – not performing sharp turns at speed or harsh braking.

On solid ground

The stability principles work fine on flat solid ground, but where there is any form of gradient at all, stability will quickly become critical. Working on ramps is common for forklifts, but trucks are their most vulnerable here if the load is elevated. For this reason trucks should always reverse downhill with the load as low as possible.

Outdoors, the dangers increases greatly. A wheel going down a small hole or up on a small ramp while the load is high can be sufficient to tip the truck over.

Attachments

If an attachment is used – like a bale clamp – the increased front-end weight moves the CCOG much further forward... significantly increasing the possibility of the truck tipping forwards. It is vital, therefore, for a driver to fully understand the changed performance characteristics of a forklift with an attachment.

Their lives in your hands

Remember, there is no such thing as a forklift truck accident. An ‘accident’ is an incident of bad driving, bad training, bad maintenance, a bad working environment or any combination of these.

- Action points

- Ensure all your forklifts have an operator restraint.

- Ensure all drivers always wear an operator restraint or seatbelt at all times – and challenge those who do not.

- Invest in driver training – and refresher courses – ensuring an understanding of safe practice.